Simple Wound Task Trainer Instructions

Revised: November 2023

Time Commitment: 60 to 90 minutes

Creators: Sébastien Perth Reviewers: Jacob Vanderploeg & Meagan Vanderploeg

Content warning: sharps

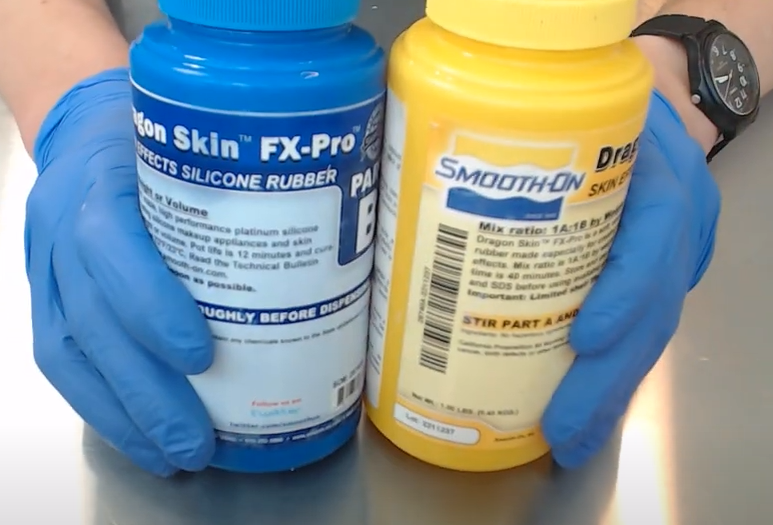

Disclaimer: these instructions will reference the silicone product Dragon Skin™ the mould-making product Smooth Cast 300™, and the pigment product Silc Pig™. This is not an endorsement or sponsorship of these products. Individuals are invited to use alternative like-products for their proto-types. Instructions below are specific to the commercial products described. Individuals who use like-products as substitutes should follow the package instructions.

What you will need

- Special Effects Grade Silicone (Dragon Skin™ FX pro Part A & B used for trainer below)

- Smooth Cast 300™ Part A & B

- Clay for walls and to texture skin surface

- Tools to shape clay (toothpicks, stir sticks, etc.) (wood tools work best)

- Disposable measuring cups (e.g. graduated medicine cups)

- Disposable larger cup (e.g. disposable drinking cup)

- Disposable stir sticks (e.g., coffee sticks, popsicle sticks, or tongue depressors)

- Silc pig™ flesh tone (optional pigment system compatible with Dragon Skin™)

- Personal protective equipment: gloves and eye protection

- Scissors

- Knife or scalpel to clean up frayed/uneven edges

- Optional: wax paper to line your container to make it easier to remove clay skin if using, or to line your worksurface if using clay to build a mould.

- Optional: rolling pin

- Optional: baby powder

- Optional: tooth brush

Instructions

| Assembly Instructions | Pictures |

|---|---|

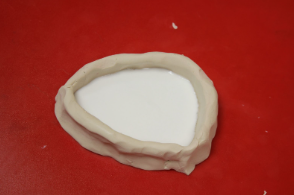

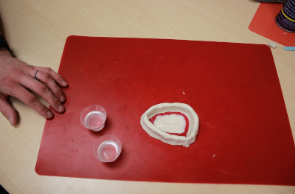

| Step 1: Prepare the wound surface On a flat surface, form clay to represent the wound you need. This may include lacerations, textured skin, etc. Try to make the transition from clay to work surface smooth, so the end product appears more natural on skin or on a manikin. Keep in mind that the clay design will be what the finished silicone looks like. Take time to clean it up if needed. TIP: If you are using clay to make a barrier, you can line your work surface with a piece of wax paper for easy cleanup. TIP: Dipping a finger in water and then rubbing it on the clay can give it a smoother texture. Just be careful not to use too much water. |  |

| Step 2: Prepare the clay walls On a flat surface, roll clay into long strips about 1.5-2” wide, and ¼” thick. The length of your pieces will be dependent on the size of your wound Ideally using clay, make a wall around the wound, leaving at least 1cm between the wound and the wall. Make sure no gaps appear that could let the Smooth Cast™ seep out. TIP: You can roll out the clay using the Smooth Cast™ bottles (securely sealed) or a rolling pin. |  |

| Step 3: Determine Smooth Cast™ amount To make a 0.75” thick layer in a 3x5” mould, you will require 180 mL of Smooth Cast™ (90ml each of parts A and B). 3/4” x 3” x 5” = 11.25in3. 11.25in3 x 16mL/in3 = 180 mL | |

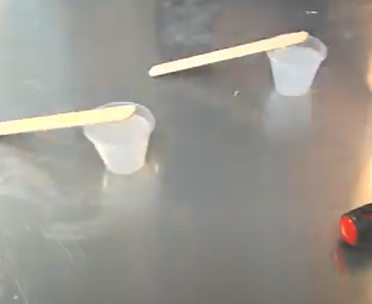

| Step 4: Pour the mould Step 4A: Open and stir Smooth Cast™ Part A. With a different stirring tool, do the same for equal parts Part B. You need enough to completely cover the clay wound by at least a few millimetres. Step 4B: Combine Parts A & B in a large cup and pour into clay walls. Ensure there are no leaks, and cover any existing leaks with more clay. Wait 10-15 minutes to let the Smooth Cast™ cure. It will become warm to the touch and opaque. | 4A  4B |

| Step 5: Cleaning the mould Once the Smooth Cast™ has hardened, you can peel away the clay which can also be reused. TIP: You may notice some thin pieces of Smooth Cast™ in the clay. You can take these pieces out if you plan on reusing the clay. The mould may have sharp edges or flashing (thin pieces of plastic). If so, use an exacto knife or scalpel to trim away any excess Smooth Cast™. TIP: Using a toothbrush to scrub with warm water can help remove clay that may still be stuck to the mould. |  |

| Step 6: Determine silicone amount If you decided to use a different size mould (i.e., not 3x5”) you need to determine how much silicone you need to fill your mould. 16 ml of silicone (8 ml each of parts A and B) will make 1in3 volume (16mL/in3). E.g., To make a 0.75” thick layer in a 3x5” mould, you will require 180 mL of silicone (90ml each of parts A and B). 3/4” x 3” x 5” = 11.25in3. 11.25in3 x 16mL/in3 = 180 mL |  |

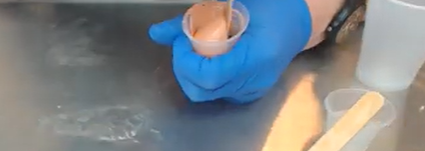

| Step 7: Prepare the surface layer of silicone Step 7A : Open and stir Dragon Skin™ Part A. With a different stirring tool, do the same for Part B. Step 7B : Using a disposable measuring cup (e.g. graduated measuring cups), measure Dragon Skin™ Part B into a disposable cup large enough to hold the final amount. Step 7C : Add flesh tone pigment(s) to Part B using a disposable toothpick or stir stick, and stir vigorously for 15 seconds/until completely combined without streaks. TIP: A little goes a long way. Start with a small amount of pigment; if you need more, add it, and stir again before adding Part A. Step 7D : Add Part A to Part B and mix vigorously for 15 seconds / until completely combined without streaks. IMPORTANT : Now that A & B are combined, you must pour it within 12 minutes, or it will begin to set. | 7A:  7C: |

| Step 8: Pour the silicone Pour the prepared silicone with the skin tone pigment of your choice into the mould. If you notice leaks, plug them with additional clay or tape. Wait 40 mins (for a 3” x 5” wound) to cure. For other sizes, follow package instructions on wait time. | |

| Step 9: Remove silicone task trainer from mould Once removed from mould, touch up any frayed edges with scissors if desired. TIP: Baby powder can be used to remove the silicone task trainer to make it less sticky and easy to remove. |

Attaching to a manikin or standardized patient

Place the wound care module on a SAM® splint or equivalent soft splint. For extra security, glue down the module to the splint. Note: check the quality of the splint prior to placing the module on top to ensure sharps do not penetrate the structure.

Secure the module to the anatomical location using either:

Important: circulation of standardized patient should be assessed if tourniquet is on for long periods.