Suturing & Staple Pad Task Trainer Instructions

Revised : November 2023

Time Commitment : 180 minutes

- Reviewer notes regarding time commitment:

- This project requires making 3 layers of silicone

- Each layer will take 40 mins to cure

- Once parts A and B are combined, they are only pourable for 12 mins – you cannot make the silicone ahead of time; you must have your mould ready to use when you make the silicone

Creator : Sébastien Perth Reviewers : Meagan Vanderploeg & Jacob Vanderploeg

Content warning: sharps

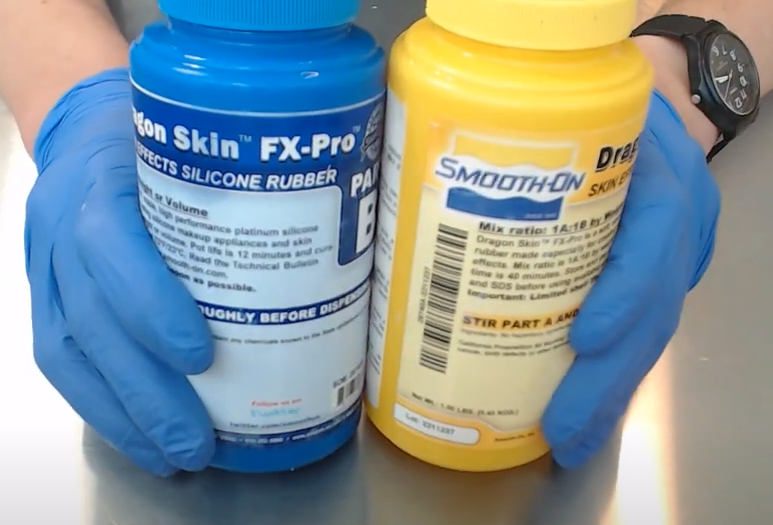

Disclaimer: these instructions will reference the silicone product Dragon Skin™ and the pigment product Silc Pig™. This is not an endorsement or sponsorship of either of these products. Individuals are invited to use alternative like-products for their proto-types. Instructions below are specific to the commercial products described. Individuals who use like-products as substitutes should follow the package instructions.

What you will need

- Special Effects Grade Silicone (Dragon Skin™ FX pro Part A & B used for trainer below)

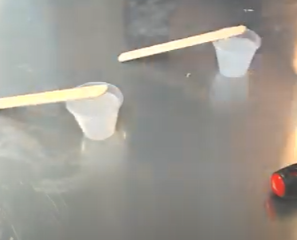

- Disposable measuring cups (e.g. graduated medicine cups)

- Disposable larger cup (e.g. disposable drinking cup)

- Disposable stir sticks (e.g., coffee sticks, popsicle sticks, or tongue depressors)

- Silc pig™ flesh tone, yellow, and blood/red colour (optional pigment system compatible with Dragon Skin™)

- Flat bottom container (e.g. 8x8, 5x9, etc.) or clay to make a mould

- Personal protective equipment: gloves and eye protection

- Power mesh fabric or thin cotton / woven fabric (the same size as your container/mould)

- Pencil

- Scissors

- Knife or scalpel to clean up frayed/uneven edges

- Wax paper to line your container to make it easier to remove clay skin if using, or to line your worksurface if using clay to build a mold.

- Optional: Clay to texture skin

- Optional: one toothpick for every Silc pig™ pigment to test and mix

- Optional: rolling pin

Instructions

| Assembly Instructions | Pictures |

|---|---|

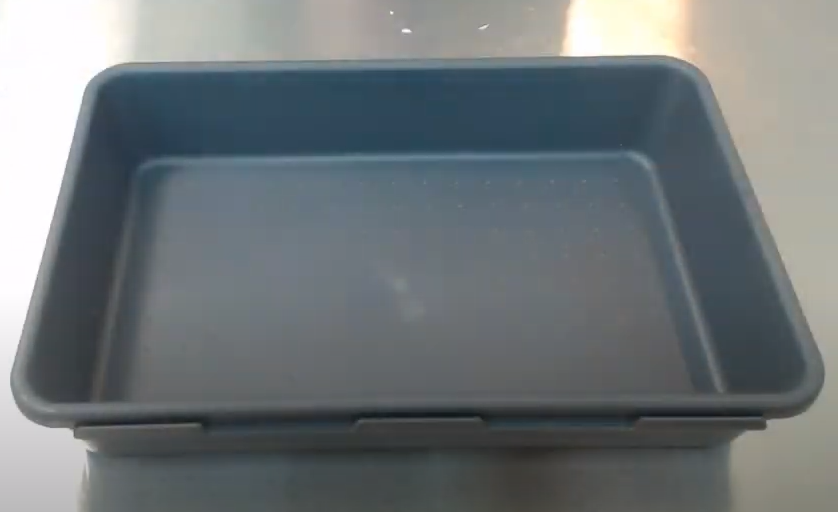

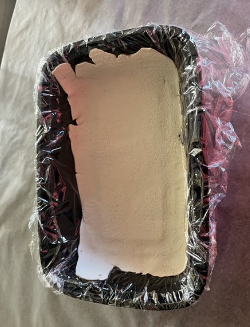

| Step 1: Prepare the mould Find a small to medium-sized container with a flat bottom, or a flat surface such as a counter or table and use clay to create a barrier/fence using clay that will become the suture pad area. Line your flat surface with wax paper. Examples of a suitable flat surface would be a kitchen counter, stainless steel surface, etc. Alternatively, use a large flat-bottomed container as your work surface with wax paper (e.g. cookie sheet). TIP: The Smooth Cast™ creates heat, so ensuring wax paper with a sturdy surface will potential minimize any damage to your work surface. TIP: We suggest a container at least 4” x 6” inches. An 8” x 8” casserole pan makes a nice size. |  |

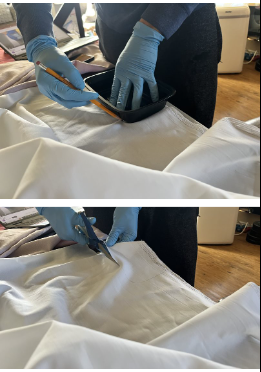

| Step 2: Measure and cut the power mesh Trace the container on a piece of power-mesh or a thin cotton t-shirt type fabric with a pencil, chalk, or marker. Cut it out, and save for later. |  |

| Optional Step 3: Add texture to mould Add a thin layer of clay to the surface where the silicone will be poured. This allows you to add texture to the clay to simulate skin. TIPS :

|  |

| Step 4: Determine silicone amounts Determine how much silicone you need to prepare for the surface layer of the skin. Aim for 1/16” thickness. TIP: 16 ml of silicone (8 ml each of parts A and B) will make 1in3 volume (16mL/in3). E.g., To make a 1/8” thick layer of silicone in a 8x8” mould, you will require 64mL of silicone (32ml each of parts A and B). 0.0625" (1/16") x 8” x 8” = 4in3. 4in3 x 16mL/in3 = 32 mL Note: the numbers in this calculation are only relevant for this layer, note the thickness of each layer to perform relevant calculations. |  |

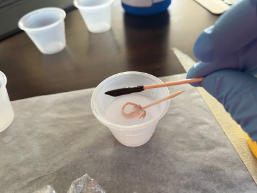

| Step 5: Prepare the surface layer of silicone Step 5A : Open and stir Dragon Skin™ Part A. With a different stirring tool, do the same for Part B. Step 5B : Using a disposable measuring cup (e.g. graduated measuring cups), measure Dragon Skin™ Part B into a disposable cup large enough to hold the final amount. Step 5C : Add flesh tone pigment(s) to Part B using a disposable toothpick or stir stick, and stir vigorously for 15 seconds/until completely combined without streaks. TIP: A little goes a long way. Start with a small amount of pigment; if you need more, add it, and stir again before adding Part A. Step 5D : Add Part A to Part B and mix vigorously for 15 seconds / until completely combined without streaks. IMPORTANT : Now that A & B are combined, you must pour it within 12 minutes, or it will begin to set. | 5A:  5C: 5D: |

| Step 6: Pour the surface layer silicone Pour the prepared silicone with the flesh tone pigment of your choice into the mould, on top of the clay (if using). Use your stirring tool (e.g. tongue depressor) to scrape down the sides of the cup. Wait 40 mins for this layer to cure. |  |

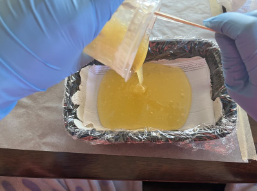

| Step 7: Prepare the adipose layer Step 7A: Place the piece of fabric you traced earlier and cover the whole surface of the cured silicone. Purpose: The power mesh/fabric allows for the suture or staple to ‘bite’ on to, preventing the sutures from tearing out or through the silicone. Step 7B: Prepare another batch of silicone just as in Step 5 except use yellow pigmentation to mimic adipose tissue. Aim for ¼” thickness. You will need more silicone for this layer compared to the surface layer. Step 7C: Starting in the center of the fabric and container, gently pour it over the silicone and fabric. Use a toothpick, stir stick or something similar to move the fabric if it shifts while pouring. Wait 40 mins for this layer to cure. | 7A  7C |

| Step 8: Prepare the muscle layer Prepare another batch of silicone just as in Steps 5 and 7 except use red/blood pigmentation to mimic muscle tissue. Aim for ¼” thickness, just like the adipose layer. Wait 40 mins for this layer to cure. |  |

| Step 9: Remove the trainer from the mould Once all layers of silicone are cured, take the task trainer out of its container or mould. If you used clay, gently separate it from the mould. If desired, rough or uneven edges of the trainer can be cut smooth with a sharp straight-edge knife, scalpel, or scissors to give the trainer a finished look. |  |

Attaching to a manikin or standardized patient

Place the suture/staple module on a SAM splint® or equivalent. For extra security, glue down the module to the splint. Note: check the quality of the splint prior to placing the module on top to ensure sharps do not penetrate the structure.

Secure the module to the anatomical location using either:

Important: circulation of standardized patient should be assessed if tourniquet is on for long periods.